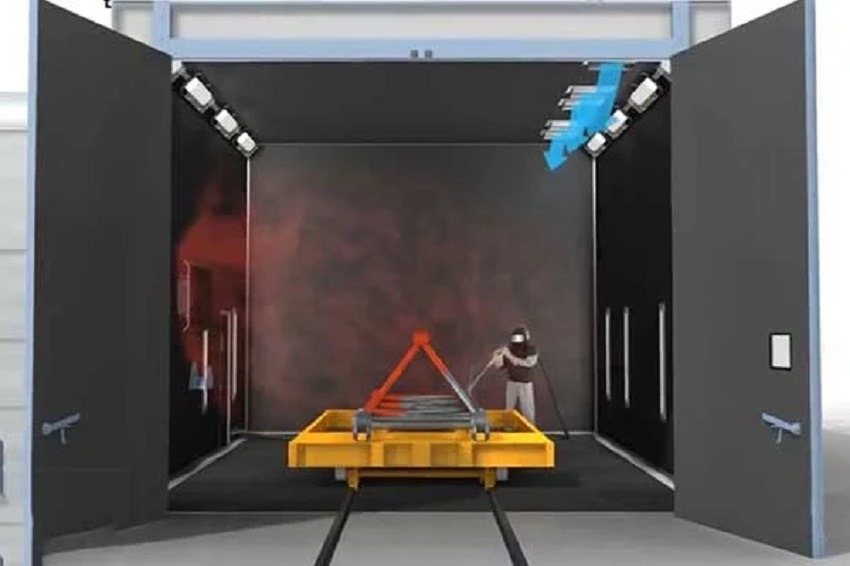

If you operate a sandblasting booth, you understand the critical role it plays in various industries, from automotive to construction. A well-maintained blast booth is essential for achieving efficient and effective surface preparation. In this comprehensive guide, we will delve into the factors influencing inspection frequency, optimal maintenance intervals, key components to monitor, industry standards, the role of preventive maintenance, and signs indicating the need for immediate blast booth inspection.

Regular Inspection Frequency

Regular inspections are the cornerstone of maintaining the functionality and safety of a sandblasting booth. To strike the right balance, consider scheduling inspections at least every six months. This frequency ensures that any potential issues are identified before they escalate into costly repairs. During these inspections, experts should thoroughly examine all aspects of the blast booth, from the dust collection system to the abrasive media handling equipment.

Optimal Maintenance Intervals for Sandblasting Booths

While a bi-annual inspection is a good starting point, it’s important to note that optimal maintenance intervals may vary based on usage and environmental factors. High-traffic blast booths in industrial settings might require more frequent check-ups, while those in less demanding environments could extend the intervals to annually. Ultimately, the goal is to prevent equipment breakdowns and maintain consistent performance.

Factors Influencing Inspection Frequency

Several factors influence the ideal inspection frequency for your blast booth. One critical factor is the volume of work processed. If your sandblasting booth handles a heavy workload day in and day out, you’ll need to inspect it more often. Additionally, the type of materials being processed and the presence of corrosive substances can accelerate wear and tear, necessitating more frequent inspections.

Environmental conditions also play a role. Dusty or humid environments can lead to faster equipment deterioration, demanding closer monitoring. Lastly, compliance with safety regulations and manufacturer recommendations should guide your inspection schedule. Ignoring these guidelines can lead to safety hazards and potential liability issues.

The Role of Preventive Maintenance in Blast Booth Performance

Preventive maintenance goes hand in hand with regular inspections. It involves proactive measures to address potential issues before they escalate. This can include tasks such as lubricating moving parts, replacing worn-out components, and conducting routine cleaning. Preventive maintenance not only extends the life of your equipment but also ensures consistent and efficient performance.

Signs Indicating the Need for Immediate Blast Booth Inspection

In some cases, waiting for the next scheduled inspection may not be an option. Certain signs should prompt immediate blast booth inspection:

- Unusual noises or vibrations during the operation

- Sudden drops in productivity or efficiency

- Increased dust emissions or reduced air quality

- Safety system alarms or malfunctions

- Visible structural damage or corrosion

Ignoring these warning signs can lead to equipment failure, costly downtime, and safety hazards.

In conclusion, the frequency of blast booth inspections should be based on a combination of industry standards, environmental factors, and the specific demands of your operation. Regular inspections, coupled with preventive maintenance, are essential for ensuring the longevity and efficiency of your sandblasting booth. By staying proactive and attentive to signs of wear and tear, you can maximize the return on your investment and maintain a safe working environment for your team.