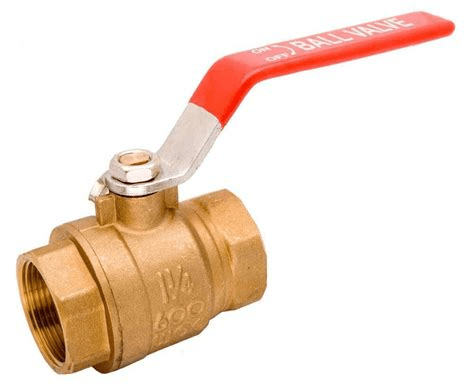

When you need a valve that has flow control, the ball valve is the one to choose. Both gases and liquids can be controlled by a ball valve. With a simple 90 degree adjustment, the liquid or gas can be allowed to flow or shut off. They last for a long time and are dependable even not used for long periods. This is why they are often favoured over gate valves.

Ball valves can even be used as a control valve, even though they can have some disadvantages when used for this purpose as there is limited accuracy in controlling flow as there is for the flow or stop function they are commonly used for. For help choosing the right Brass Ball Valve for your needs, contact https://orseal.com/

There are different types of ball valves that include:

- Hydraulic – Resistant to heating oil and able to operate under high pressure, these valves are often made from steel or stainless steel.

- Standard – These valves consist of a housing, seats, ball and lever for rotating. They are tough against high pressure and heated environments and have a broad range of applications.

- Vented – These are handy in compressed air systems as there is an outlet port that when the valve closes, releases pressure through a vent.

- Flanged – These valves are designated by their connection ports. Ports connect to piping systems via flanges and these valves are used in applications that require a high flow rate.