Warehouses often stretch out very far, requiring their workers to walk for miles in an average shift. Much of the work is routine, so some warehouses are turning to robots as a way of picking stock in a more efficient manner without the need for paid workers. Robots can also be used for movement, which means human workers can spend more time on more creative tasks whilst leaving the robots to do the walking.

The use of robots in warehouses means that less time is spent walking from place to place to find stock. Robots make picking and delivering goods to customers a faster process. This means more profits can be made for everyone involved in the production process.

Ocado Smart Platform

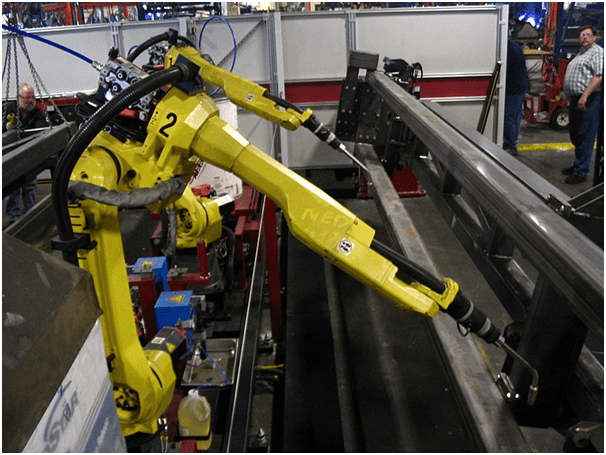

For example, online grocery store Ocado has unveiled a new idea called the Ocado Smart Platform. With this system, robots bring the stacks of shelves to the human workers who can pick out the correct products to send to the customers. The robots can travel at higher speeds than humans and cover many miles, speeding up the selection process.

Shelves containing products in warehouses have to be hardy and versatile in design. For example, industrial shelving in Ireland from stockists such as https://www.rackzone.ie/shelving/industrial-residential-shelving allows large numbers of products to be stored conveniently and safely in a warehouse. Robots can work their way between the well-designed shelves and move them to the human workers to select products.

Amazon and KIVA Systems

Amazon uses a similar system, which was developed in 2012 by KIVA systems. This makes use of a flat warehouse floor that brings the shelves of goods to the human pickers. Amazon has its Amazon Robotics systems in place in some of its UK warehouses, and it plans to extend their use in the coming years.

Other hopes for the future include swarm robots that can communicate with each other. This will make it possible for robots to complete a complex task involving many items, with robots able to select items to complete the orders without so much help from humans.

Another issue is the fragility of objects. A more sensitive robot hand could handle fragile and delicate objects without needing any prior knowledge of the object’s shape. At the moment, this is a problem for robots as they cannot grasp firmly without risk of breakage.